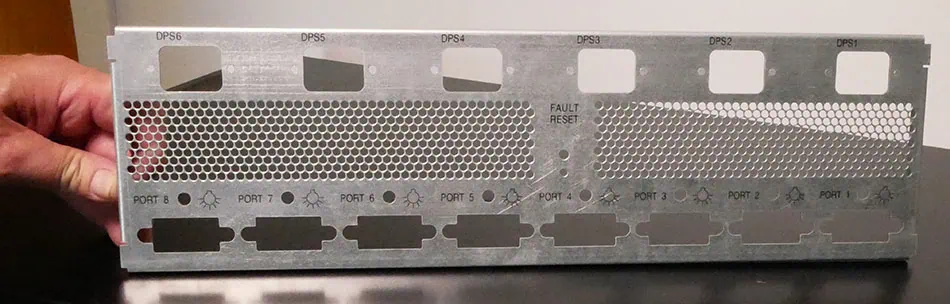

Greater Precision

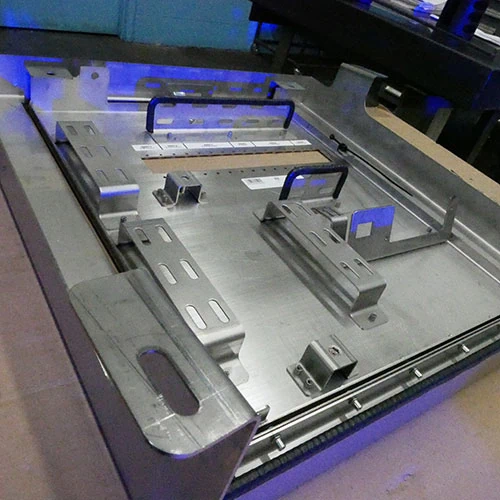

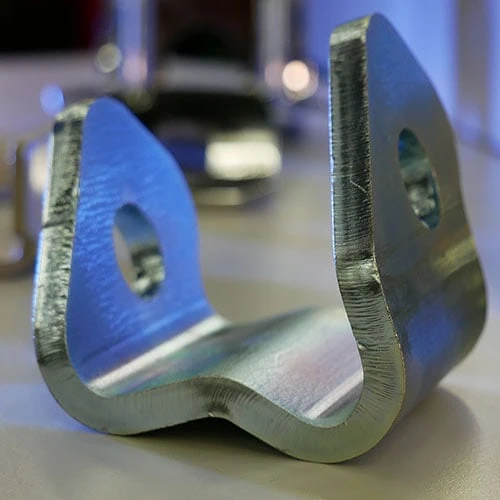

Acro Industries, Inc. can provide complete sheet metal fabrication services for your project using our wide array of cutting, bending, and punching capabilities.

Laser Cutting – Our Cincinnati 707 Laser uses a 3300-watt laser to cut through a maximum material thickness of 7/8″. The flying optics allows the material to remain stationary while the cutting laser moves to provide greater precision. The worktable is 120″ x 60″ which allows for creation of single large products or multiple smaller products in the same run.