Contract manufacturing encompasses the diverse range of services a manufacturer offers to develop products for another company. These capabilities can vary, but typically include engineering, industrial control design, prototyping, quality control, packaging, supply chain management, and various manufacturing methods, such as assembly, machining, and molding.

Acro Industries, Inc. is a certified contract manufacturer that serves a diverse range of customers in demanding industries, including medical, aerospace, and defense. By leaning on our specialized contract manufacturing equipment and expertise, our customers can focus on other core aspects of their operations. Learn more about our comprehensive range of capabilities and how they meet the demands of various critical industries.

Industrial Welding Services

Industrial welding is a primary service for maintenance, manufacturing, and construction industries. The technique can create a vast array of structures and products, from steel bridges and pipelines to precision parts in medical devices and aerospace applications.

Welding utilizes pressure, heat, or a combination of the two to join metal components. The process produces a fortified bond that can withstand the demands of stress and extreme environments.

The benefits of our industrial welding services include:

- Affordability

- Durable joints

- Operational efficiency

- Product and material versatility

- Strength

At Acro Industries, Inc., we have decades of welding experience and quality assurance protocols in place to execute projects with consistent precision and accuracy.

CNC Machining

Acro Industries, Inc. employs CNC machining services to fulfill our clients’ machining requirements. Our largest capacity CNC machine has a work envelope of 55″ x 47″ x 53″, allowing us to create components weighing up to 6,000 pounds. This cutting-edge machine features 140 unique tools to create complex contours, cuts, and shapes.

Electro-Mechanical Assembly

Since each electro-mechanical assembly is engineered to carry out a specific function, we start the manufacturing process by understanding the design intent and underlying goals of the project. This step is crucial when an assembly must be integrated into a larger product.

The process begins with a comprehensive review of the application’s functional requirements, including operating conditions, safety requirements, and space limitations. Dimensions, tolerances, circuitry, and component materials are also addressed and designated in the schematics and blueprints.

While some products can be assembled in a standard manufacturing environment, others require a cleanroom or controlled setting. Assembly can be performed manually by a skilled operator or via automated equipment, such as:

- Pick-and-place operations

- Robotic arms for soldering

- Verification/Inspection equipment

Quality control includes functional testing, verifying the electrical output of a system, and visual inspection. The assembly components or process can be adjusted or refined at potential points of failure or when errors are discovered during any step of the electro-mechanical assembly process.

Custom Laminate Panels

Our laminating process involves bonding an inner core with two exterior skins to create a new composite with enhanced properties. We often utilize this technique to apply an adhesive film, but we can also create laminate panels with the following attributes:

- Better resistance to heat or wear

- Enhanced surface protection

- Improved strength-to-weight ratio

Laminating requires an adhesive that is bonded by either heat or cold pressure to effectively join materials, such as aluminum honeycomb, foam, plastic film, steel, or wood. This process is extremely versatile, which makes it an ideal solution for a broad range of applications, including:

- Laboratory medical equipment

- Marine applications

- Railway components

- Recreational vehicles

- Trucks

Our panel laminating services offer improved durability and performance, extensive branding opportunities, enhanced functionality, improved efficiency, and cost-effectiveness.

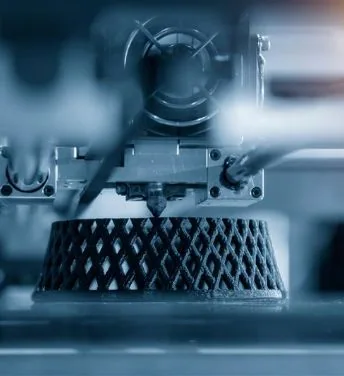

Rapid Control Prototyping

Rapid control prototyping (RCP) is a technique that enables engineers to quickly test control strategies using real-time software and hardware, eliminating sole reliance on simulations. This approach offers faster development cycles, better control algorithms, and reduced risk by identifying issues at the initial stages of the design process.

The prototype department at Acro Industries, Inc. supports a wide variety of applications, including but not limited to:

- Full assemblies

- Prototyping individual parts

We also work with a comprehensive line of press brakes, non-tooled systems, CNC lasers, and short-run manufacturing methods that can integrate seamlessly with SLA plastic and sheet metal assemblies.

Acro Industries, Inc. has the unique ability to handle both full production and short-run prototypes in-house. As customer requirements change, we can handle requests promptly.

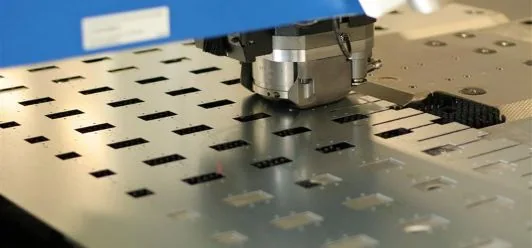

Metal Stamping

Metal stamping utilizes specialized dies and a press to shape and cut flat metal coils or sheets into desired components. This cold-forming manufacturing process is a cost-effective and highly efficient method for producing large volumes of precise, high-quality parts with superior repeatability. The process involves placing the metal between the die and punch, and then applying high pressure to cut or form the metal into the desired design.

Acro Industries, Inc. specializes in stamping, providing high-quality components for applications across a range of industries, including:

- Aerospace

- Automotive

- Electrical

- Medical

- Railroad

Our extensive experience working with a diverse customer base enables us to efficiently and quickly produce all parts and necessary documentation for the project. We can conform to internal product specifications and/or nationally accepted standards, depending on the specific requirements of the application.

Acro Industries, Inc. employs advanced stamping techniques and equipment that can achieve tolerances down to +/- .0005″, ensuring the necessary fit and functionality of each part. Our metal stamping capacity ranges between 30 tons and 600 tons with electric feed lines. Our manual feed punch presses have a 60-ton limit, and we also have a multi-action 500-ton hydraulic press for larger runs.

Quality Contract Manufacturing From Acro Industries, Inc.

With over 50 years of proven industry experience, Acro Industries, Inc. provides a full range of contract manufacturing services that seamlessly integrate with our customers’ operations. While we possess the resources and expertise of a large company, we provide the focused attention of a dedicated and reliable partner.

Request a quote today and see how the contract manufacturing experts at Acro Industries, Inc. can meet the unique demands of your next project.